National Grating FRP Solutions Improve Safety in Slippery Winter Conditions

Winter is approaching and preparation to improve slippery and dangerous walkways has to begin soon. Not to worry! National Grating has a large inventory of FRP solutions that improve safety in slippery winter conditions.

Slips and falls are some of the biggest causes of injuries in North America whether that is at work or at home.

For business owners and operators, it is crucial to have a safe place of business for your customers to enjoy. For homeowners and the contractors that build them, it is a must to provide your family and friends with safe walkways where everyone feel safe.

National Grating takes safety very seriously. We specialize in FRP walkway solutions that improve safety in all conditions and especially when inclement weather creates dangerously slippery walkways and stairs.

Anti Slip FRP Solutions

We have a full complement of molded and pultruded FRP Grating with an added grit coating. The gritted surface provides excellent traction, reducing the risk of slips and falls, especially in wet or icy conditions.

National Grating provides gritted molded FRP grating, pultruded FRP grating, FRP stairs, FRP stair tread covers and FRP plate.

National Grating FRP Grating solutions are perfect for winter conditions:

FRP grating solutions from National Grating are particularly well-suited for winter conditions due to several key features:

Exceptional Slip Resistance: The gritted surface of FRP grating provides excellent traction, even when wet or covered in snow and ice. This significantly reduces the risk of slips and falls, ensuring safer walkways and work areas.

Corrosion Resistance: Winter often brings exposure to salt and de-icing chemicals, which can be corrosive to traditional materials like steel. FRP grating is highly resistant to corrosion, maintaining its integrity and safety features throughout the season and for many years.

Low Thermal Conductivity: FRP does not readily transfer heat or cold, meaning it won’t become uncomfortably cold to the touch. This is particularly beneficial for handrails and other surfaces that people frequently touch.

Durability and Low Maintenance: FRP grating is resistant to rust, warping, and the effects of freezing and thawing. This durability ensures that the grating remains functional and safe with minimal maintenance.

Easy Installation: The lightweight nature of FRP grating makes it easy to install, even in challenging winter conditions. This can save time and resources during installation.

These features make molded FRP grating from National Grating an excellent choice for maintaining safety and functionality in winter environments.

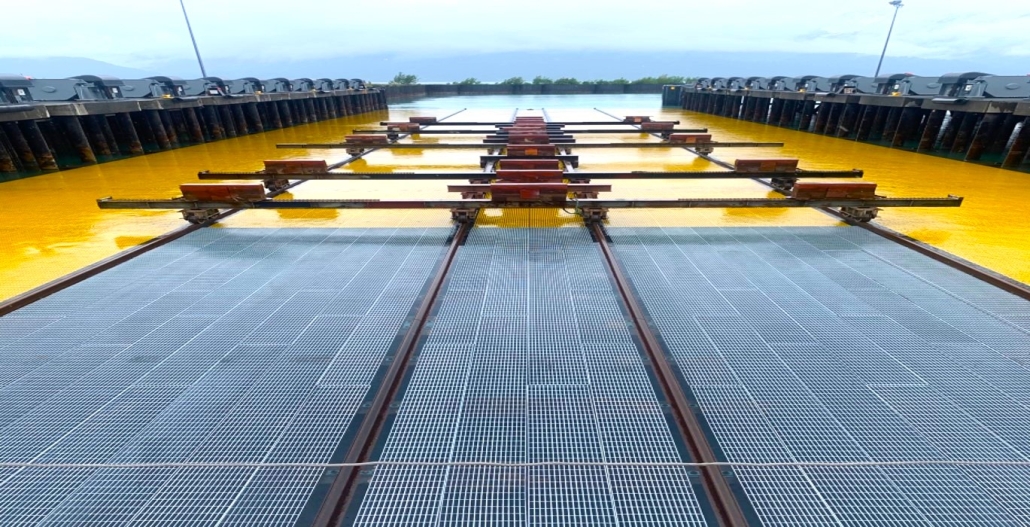

Molded FRP Grating

National Grating Molded FRP Grating offers bi-directional strength due to the interlacing of continuous fibers in multiple directions.

The ultimate safe walking surface for walkways, docks with an optional gritted anti-slip top surface that promotes safety while the large open area of the grating allows for water, snow and ice to simply pass through the material.

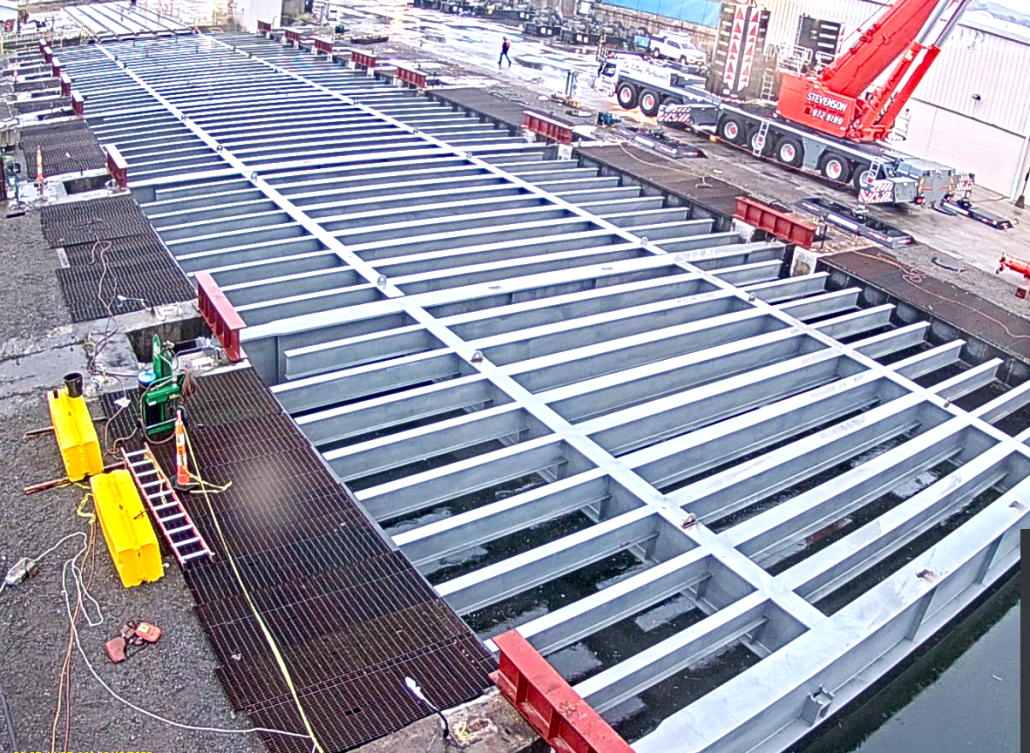

Pultruded FRP Grating

Pultruded FRP grating is known for its high strength-to-weight ratio. The continuous glass fibers provide exceptional strength in the direction of the load bars. This allows it to to support longer span compared to molded.

Available in I and T bars with space between each bar to ice, snow and water to fall between reducing snow and ice buildup.

FRP Stair Treads and Covers

FRP Stair tread covers can be installed over wood, concrete or metal steps and are manufactured with a quartz grit-top surface and a standard nosing of highly visible yellow.

FRP Stair Tread Covers

National Grating offers molded and pultruded stair treads with reinforced yellow nosing for the ultimate in safe, grippy stairs that are highly visible.

Gritted Plate

Fiberglass Plate is industrial anti-slip flooring that is corrosion resistant and outlasts traditional building materials like steel and even stainless-steel plate. Slippery wooden walkways, ramps, decks and docks can be easily improved by simply installing grit top FRP Plate over the existing walking surface.

HLC FRP (High Load Capacity)

With a much higher strength-to-weight ratio, molded HLC fiberglass grating has optional top grit to provide extra grip in slippery outdoor applications for vehicles and heavy traffic.

Tube and Handrail

Fiberglass Railing, Handrail and Ladder Systems are a long-lasting, low-maintenance solution for harsh outdoor environments. FRP railing systems provide low thermal conductivity making them safer to use as hand rails and ladders in cold conditions.

National Grating Fiberglass Reinforced Plastic (FRP) Solutions:

- Molded FRP Grating

- Pultruded FRP Grating

- Mini Mesh FRP Grating

- Heavy Duty / High Load Capacity FRP Grating

- Structural Shapes

- Stair Treads and Covers

- Fiberglass Plate

- Fiberglass Tubing

- Fiberglass Railing

- Threaded Rod and Nuts

- Grating Clips

- Specialty Products

National Grating Customer Service

National Grating prides itself on providing exceptional customer service to all customers, big and small.

Reach out to us today for your next FRP Project!

Sales@NationalGrating.com / 1-844-599-0260