National Grating Announces Eastern Facility Expansion in Woodstock, Ontario

National Grating (www.NationalGrating.com) a leading North American provider of FRP Grating and FRP (Fiberglass Reinforced Plastic) Composite Structural solutions, is proud to announce an eastern facility expansion to a new location in Woodstock, Ontario, Canada. This strategic expansion is in response to the growing demand for FRP products and the company’s commitment to providing exceptional service to its customers.

“We have expanded our Ontario operations by moving to a new two-acre facility just 10 mins from Highway 401 with 5,000+ pieces of Fiberglass FRP Grating, Shapes, Beams and Structure in stock.” Dylan Powell, Sales Manager. “This Eastern Distribution facility will help us to service our customers up and down Eastern North America. We work hard to commoditize FRP and make it accessible and available to the consumer!”

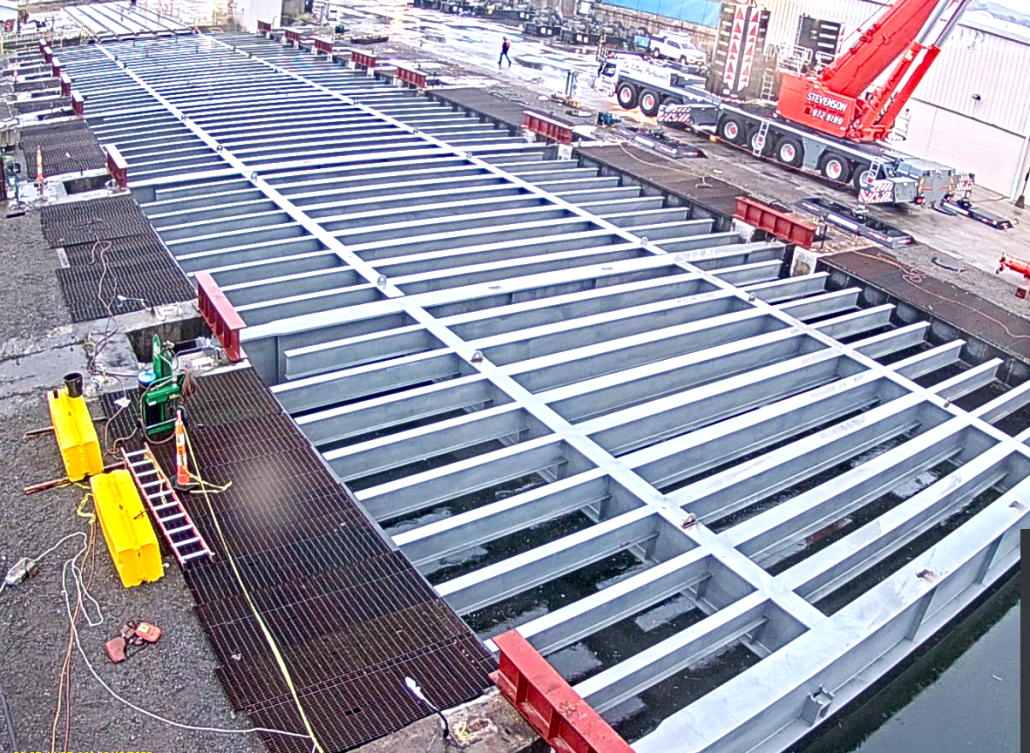

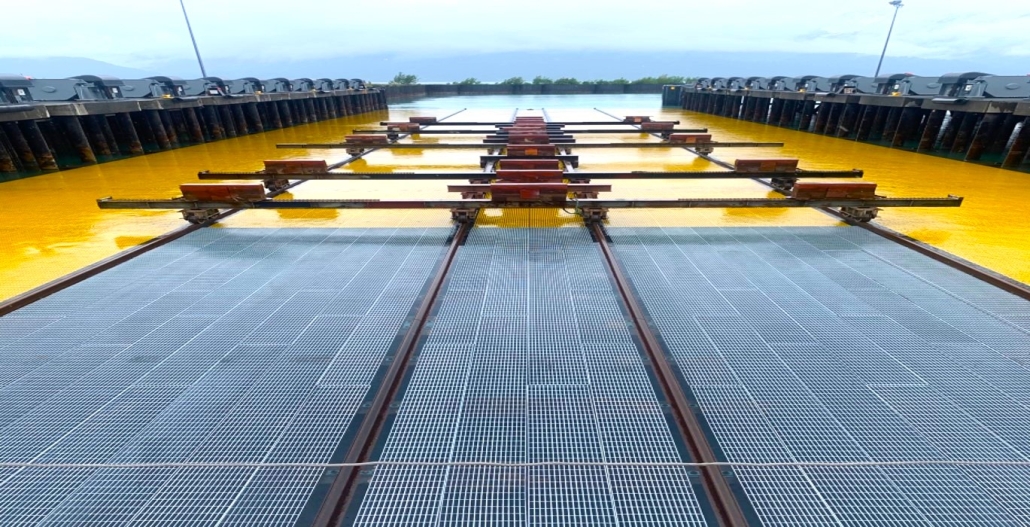

The new facility boasts a large inventory of FRP products, including bulk FRP molded and pultruded grating, as well as a wide range of specialty items such as FRP Stair Tread, Fiberglass Plate, Fiberglass Railing, Fiberglass Tubing, Fiberglass Beams, Fiberglass C-Channel, Fiberglass I-Beams, Fiberglass H-Beams and FRP Threaded Rod and Nuts. With this extensive inventory, National Grating is well-positioned to serve the needs of metal fabricators, contractors, and construction companies in Ontario in beyond. The company’s ability to ship quickly for projects, coupled with its custom fabrication services, makes it a valuable partner for businesses seeking durable and versatile FRP solutions.

“We will maintain our Western branches in Vancouver and Kelowna in British Columbia and Spruce Grove in Alberta in addition to our dozen stocking locations across the USA. We have always prided ourselves in having the best customer service in the industry and this expansion is to ensure that continues.” Rick Van Rikxoort, National Grating President.

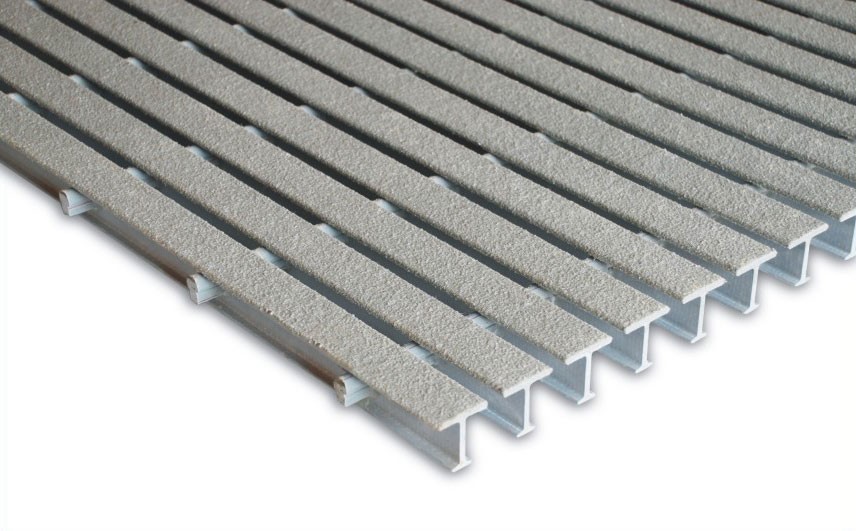

The Ontario facility will offer a complete line of FRP solutions for various applications, including walkways and platform grating, railings, and stair treads with a non-slip ADA compliant finish.

“Feel free to drop by our newest location to view thousands of FRP Grates and Shapes in stock!” Dylan Powell, Sales Director “Pickup a sample when you go! We have tons of inventory to look at and tons of samples to take back to your office to show your staff the quality that goes into our products.

The Ontario facility will offer a complete line of FRP solutions for various applications, including walkways and platform grating, railings, and stair treads with a non-slip AODA, ADA compliant finish. In addition, National Grating’s FRP products are known for their corrosion resistance, significant weight savings, and ease of installation, making them an ideal alternative to traditional materials.

National Grating’s new Eastern Distribution Center represents a significant step forward in furthering the company’s commitment to service and quality and strengthening the company’s ability to serve its valued customers across North America. With its extensive inventory and superior logistics network, the company is well-equipped to provide fast delivery of fiberglass grating all major cities in Eastern Canada and the USA.

National Grating has experienced huge growth over the past several years. We saw a need for an Eastern distribution hub to better serve our customers in the area. The massive amount of metal fabricators and contractors that have been switching over to our FRP Grating products has really been the impetus for his new location and we look forward to providing them with exceptional service.” Dylan Powell, National Grating Sales Director.

“We pride ourselves on providing the absolute best customer service in the industry with dedicated sales support, fast shipping and a great product. Give us a call and talk to a real person about your projects FRP needs.” Rick van Rikxoort, National Grating President.

National Grating Ontario Distribution Center FRP Solutions & Services

- Bulk Inventory

- National Grating specializes in having high levels of inventory on hand. This allows customers to view the product at our facility while also allowing us to quickly send samples and products to your office, factory, or construction site.

- Custom Fabrication Services:

- Our FRP experts are highly experienced in providing custom solutions to a variety of applications. Whether requirements call for grating cut to specific lengths, widths or sizes, our fabrication department has the experience to accommodate a variety of requests. Custom services are offered by the new National Grating Ontario location with an in-house fabrication shop and experienced professionals who work closely with clients to turn their design concepts into high-quality finished products.

- National Grating fabrication services involve the use of advanced fabrication techniques and technical expertise to produce custom FRP structures, grating, platforms, handrails, beams, and other products. Custom FRP fabrication services provide corrosion-resistant, durable, and customized solutions that meet specific design and functional requirements.

- On-site Training and Education

- We are FRP experts with years of experience that we want to share. If you are interested in booking one of our local FRP experts to educate you and your team on FRP applications, uses and advantages please contact us at:

1-844-599-0260 or sales@nationalgrating.com

- We are FRP experts with years of experience that we want to share. If you are interested in booking one of our local FRP experts to educate you and your team on FRP applications, uses and advantages please contact us at:

National Grating Fiberglass Reinforced Plastic (FRP) Grating Solutions in Ontario:

- Molded FRP Grating

- Pultruded FRP Grating

- Heavy Duty / High Load Capacity FRP Grating

- Structural Shapes

- Stair Treads and Covers

- Fiberglass Plate

- Fiberglass Tubing

- Fiberglass Railing

- Threaded Rod and Nuts

- Grating Clips

- Specialty Products

National Grating Ontario Location:

684470 Road 68

Beachville, ON, Canada

N0J 1A0

Just outside Woodstock across from the Oxford Drive In – minutes from the 401 – 1.5 Hours from Toronto and ~ 2 hours from Detroit or Buffalo crossings.

About National Grating – FRP Solutions

National Grating is a North American provider of FRP Grating and Structural solutions. The company offers a wide range of FRP products and fast delivery via its superior logistics network. With a focus on quality, durability, and customer satisfaction, National Grating is a trusted partner for businesses across North America. For more information about National Grating and its FRP products, visit nationalgrating.com.