What are Fiberglass Reinforced Plastic (FRP) Structural Shapes, and what are they used for?

FRP Structural Shapes are Beam, Angle, Channel, Plate, Rod, Tube and other Custom Shapes/Sizes made with pultruded Fiberglass Reinforced Plastic instead of traditional materials like steel. This gives them certain advantages that are similar to our Molded and Pultruded FRP Grating.

At National Grating we don’t just sell FRP, we sell FRP solutions. Part of that offering is in the form of FRP Structural Shapes like Fiberglass Beam, Fiberglass Angle and Fiberglass Tube. On this page we will go over what these FRP products are, and what they are used for.

National Grating FRP Structural Shapes

Benefits of FRP Structural Shapes from National Grating:

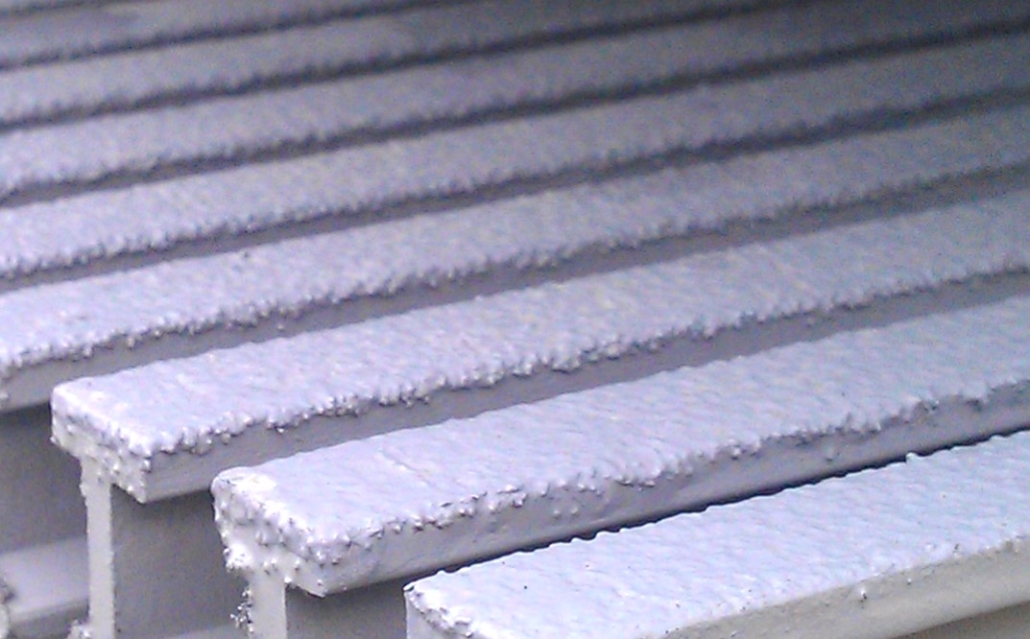

Corrosion resistant: FRP won’t rot, rust, or corrode.

Strong, yet lightweight: Choosing FRP ensures savings on transportation and installation costs, since heavy duty equipment is seldom needed.

Virtually maintenance-free: Durable and weather-resistant for a longer life cycle.

Fire-retardant and nonconductive: Creates a safer environment free of electrocutions and fire related injuries.

Dimensionally stable: Won’t shrink, swell, warp, or bow.

Highly consistent: Strength, appearance, and quality are the same from piece to piece.

Easy to fabricate and install: FRP can be cut, drilled and assembled with standard tools and is lightweight, eliminating the need for heavy duty construction equipment.

Non-leaching: Does not require environmentally hazardous preservatives to maintain visual integrity.

Fast turnaround: Most in-stock orders are shipped within the next business day.

What are FRP Structural Shapes used for?

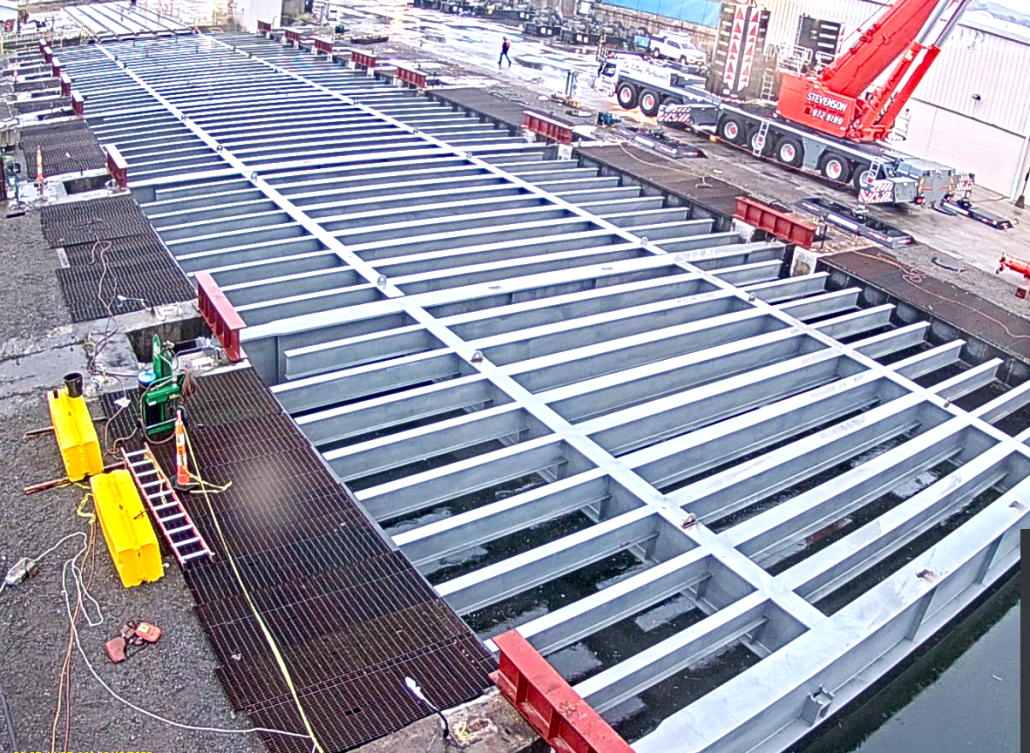

• Industrial and Commercial Settings: FRP shapes are employed in industrial and commercial settings for applications such as railings and ladder systems. They offer durability and resistance to corrosion, making them suitable for heavy-duty use.

• General Construction: The lightweight yet durable nature of FRP shapes makes them suitable for general construction applications where a high strength-to-weight ratio is required.

FRP shapes can be used in various structural applications to provide long-lasting, corrosion-resistant solutions. They are often utilized to reinforce wooden structures, strengthen columns and beams, and retrofit structures for seismic resistance.

• Structural Engineering: FRP profiles such as tubes, rods, channels, and angles, are used in structural engineering applications for new construction, as well as for reinforcing and strengthening existing structures.

They are employed in the construction of beams, columns, walls, and façade systems due to their high strength, lightweight nature, and corrosion resistance.

• Seismic Retrofitting: FRP shapes are utilized for seismic retrofitting to enhance the resistance of structures to earthquakes.

They are applied to increase the seismic resistance of concrete columns, beams, walls, and floors, thereby improving the overall strength and durability of the structures.

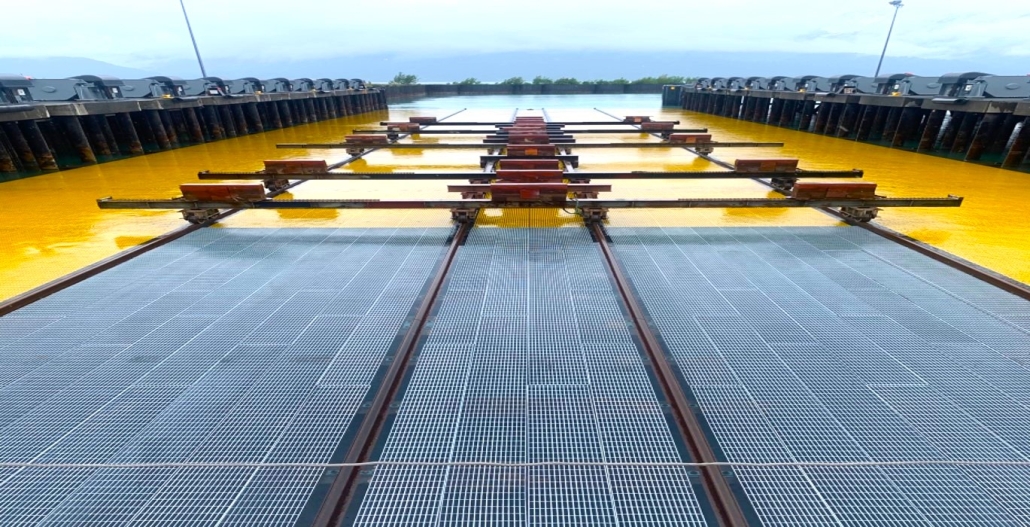

• Infrastructure Components: FRP shapes find application in the construction of various infrastructure components such as tanks, manhole covers, and bridge rehabilitation.

Their resistance to chemicals, durability, and low-maintenance properties makes them ideal for infrastructure applications.

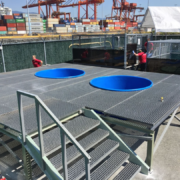

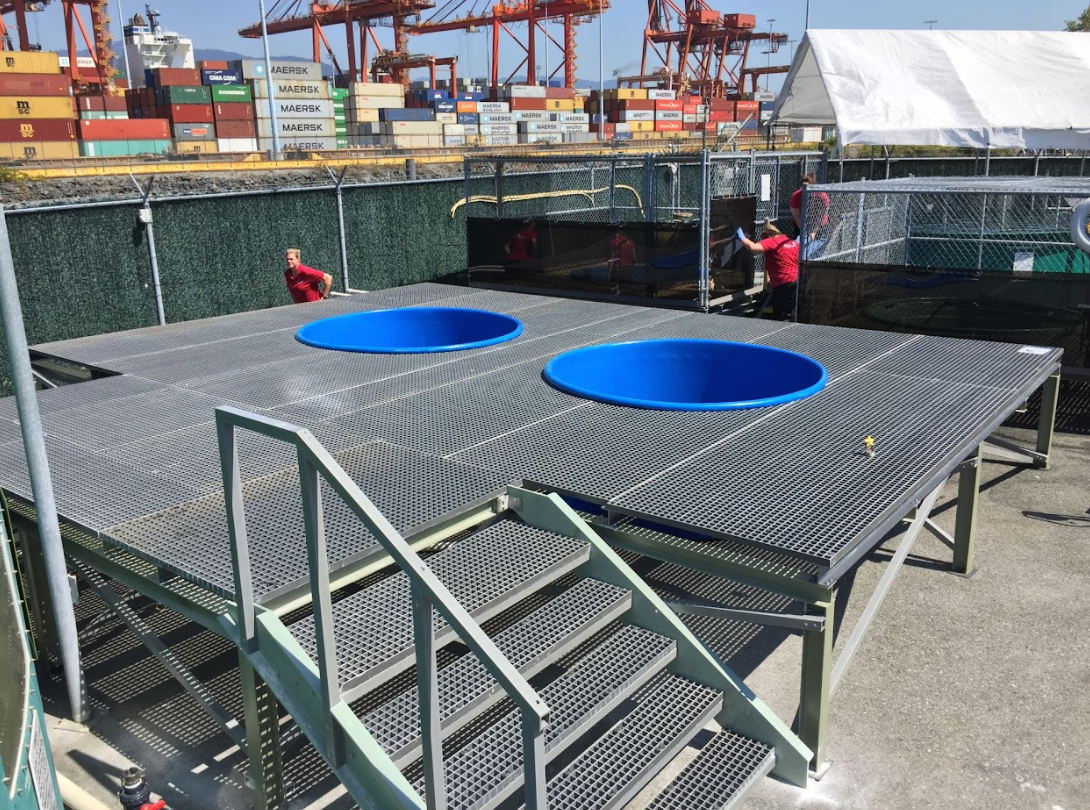

• Corrosive Environments: Fiberglass structural shapes are well-suited for use in corrosive environments, such as in the chemical processing industry, water treatment plants, and marine applications, due to their excellent corrosion resistance. Water parks and theme parks utilize FRP structures and grating for its ability to stand up to chlorinated water without rotting or corroding.

• Electrical and Telecommunications: Fiberglass I-beams and C-channels are non-conductive, making them suitable for use in applications where electrical currents or electromagnetic interference are a concern, such as in telecommunications infrastructure.

• Safety Applications: FRP Structural shapes are popular in safety industry applications such as ladders, safety cages, safety railings, and platforms due to their light weight and strong nature.

FRP Structural Shapes Sizes, Shapes and Colors from National Grating

All standard FRP Structural shapes come in 20’ lengths, SPFR resin, and grey color.

Other options, sizes and colors are available upon request.

National Grating Customer Service

National Grating prides itself on providing exceptional customer service to all customers, big and small.

Reach out to us today for your next FRP Project!

Sales@NationalGrating.com / 1-844-599-0260

National Grating Fiberglass Reinforced Plastic (FRP) Grating Solutions:

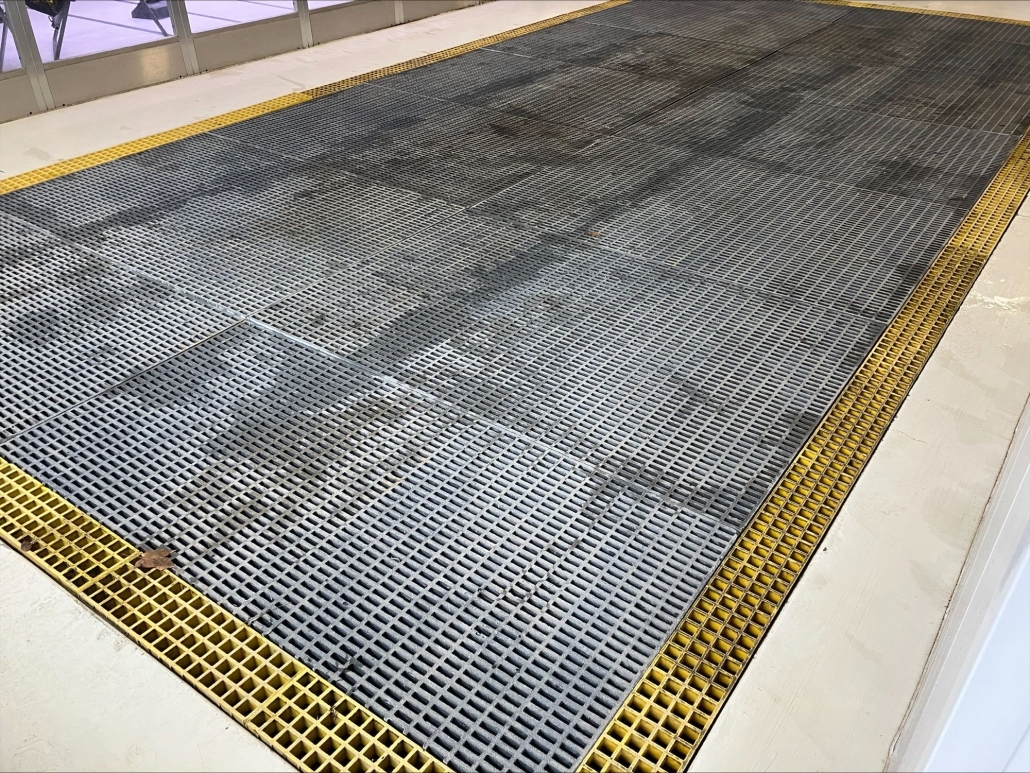

Fiber Reinforced Plastic (FRP) grating has gained significant popularity in wide variety of industries due to its exceptional properties and versatility. FRP grating is a strong, lightweight, and durable product with excellent corrosion resistance, high strength-to-weight ratio, and low maintenance requirements making it an ideal choice for hundreds of different applications.

Fiber Reinforced Plastic (FRP) grating has gained significant popularity in wide variety of industries due to its exceptional properties and versatility. FRP grating is a strong, lightweight, and durable product with excellent corrosion resistance, high strength-to-weight ratio, and low maintenance requirements making it an ideal choice for hundreds of different applications.

You will find

You will find